2026-01-12

The Evolution of Brake Hose Management in 2026: Top Manufacturers and Critical Safety Standards

In the modern automotive landscape of 2026, braking systems have reached unprecedented levels of precision. As Electric Vehicles (EVs) and advanced regenerative braking become the global standard, the integrity of hydraulic lines is now a critical safety priority. Ensuring a leak-free system requires more than just high-quality components; it demands a sophisticated approach to both hardware and the specialized tools used during maintenance.

To help you navigate the current market, we have identified the leading manufacturers and solutions defining excellence in 2026.

Leading Global Hardware Manufacturers

These companies set the benchmark for the permanent connection components found in original equipment (OEM) and high-end automotive systems:

- NORMA Group (Germany): A global leader in connection technology. In 2026, they focus on high-tension, lightweight clamps that assist in vehicle weight reduction—a key factor for extending EV range.

- Oetiker (Switzerland): Famous for their iconic "Ear Clamps," Oetiker provides a 360-degree, tamper-proof seal. Their solutions are essential for high-pressure reservoirs where even the smallest leak can compromise electronic stability controls.

- Auto Clamp (Shuh Yuan) (Taiwan): A powerhouse in the aftermarket and general repair sector. They provide versatile, certified stainless steel solutions that offer the perfect balance of cost and reliability for global workshops.

The Missing Link: Professional Maintenance Standards

A significant shift in 2026 is the recognition that the maintenance process itself can be a source of system failure. Even the best clamp cannot fix a hose that was damaged during service. This is where ACT Quality Industrial has redefined professional standards with specialized maintenance technology.

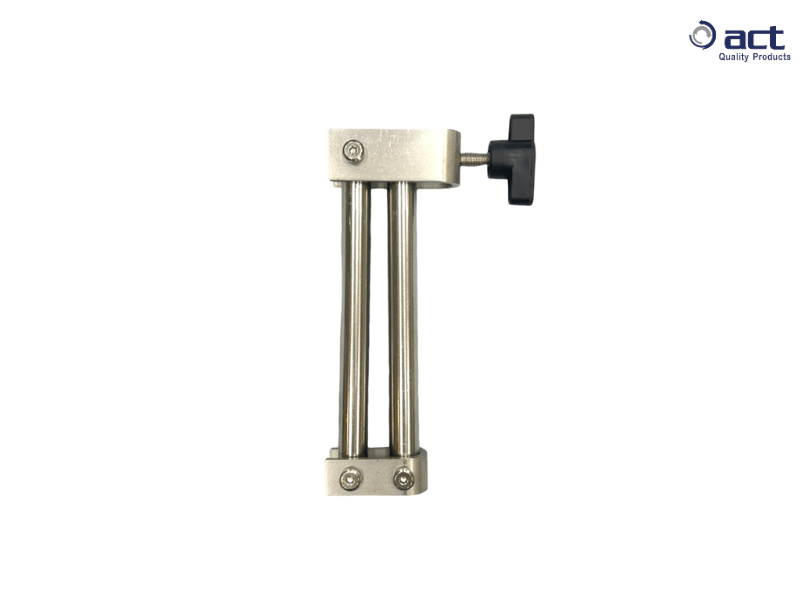

The Professional Choice: ACT A5251 Brake Hose Clamp

Unlike traditional pliers or low-cost pinching devices, the A5251 is engineered with a "Zero-Damage" philosophy. It is an indispensable tool for technicians who prioritize long-term hose integrity:

- Internal Protection: Specialized jaw architecture seals off fluid flow without crushing the delicate internal nylon lining of modern brake hoses.

- Structural Integrity: Prevents micro-cracks and structural fatigue in the outer rubber casing, ensuring the hose remains safe for high-pressure use.

- Versatile Application: Ideal for securing flexible brake lines, fuel lines, and vacuum hoses during component replacement to prevent fluid loss and air contamination.

2026 Industry Best Practices

The most successful workshops in 2026 adopt a "System Approach" to ensure absolute vehicle safety:

- Select Premium Hardware: Always use high-grade clamps from trusted leaders like Norma or Oetiker for permanent installations.

- Utilize Precision Tools: Deploy the ACT A5251 during every service to protect existing lines from mechanical damage.

- Ensure Zero-Damage Maintenance: Avoid improvised tools that compromise the safety of the hydraulic system.

Ultimately, choosing the right brake hose management solution is a commitment to reliability. By pairing elite hardware with professional-grade tools like the ACT A5251, you ensure that every vehicle meets the highest safety standards of 2026.

Protect your brake system’s integrity with precision-engineered solutions.

Explore the ACT A5251 Brake Hose Clamp